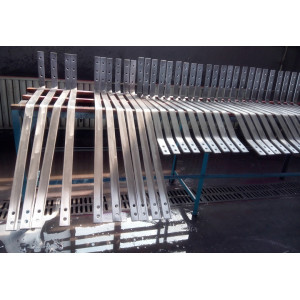

Titanium clad Copper bending punch pieces

Extrusion process: put thebase material copper bar and the composite material

titanium tube set together,after extrusionprocess, make the copper bar and the titanium tube preliminary compositetogether,formation of titanium copper billet material.

Hot rolling process technology: put the titaniumcopper billet material into the hole pattern rolling mill, hot rolled intorequired size, make the titanium and copper reach the certain compositestrength. Then straightening, surface treatment processes such as, eventuallybecome a finished product.

Detection means for titanium copper compositebar: Ultrasonic flaw detection, inspection titanium copper composite bar joint.

Penetrationtesting, inspection titanium copper composite bar

weldingconditions.

- Phone

- *Title

- *Content

- Name:

- Ms.Candy Nan

- Tel:

+0086-0917-6758968

+0086-13892437457

- Email:

- btgty@vip.163.com

- WhatsApp:

- 8613892437457

- Address:

- No.21 Road High Technology Zone,Baoji, Shaanxi,China.