- Titanium Seamless Tube

- Application of Titanium Cathode Plate in electrolytic and hydrometallurgical industry.

- The performance of the non-ferrous metals nickel, tantalum, niobium and uses

- Titanium Screws & Nuts

- The performance of Titanium

- The performance of stainless steel

- Immersion anode(Ti/Cu,Zr/Cu,Stainless steel /Cu...) advantages

- Titanium material using application areas

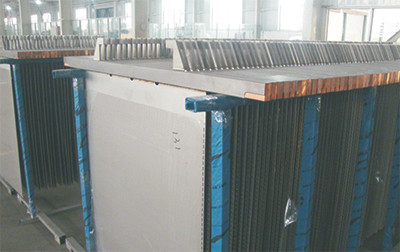

What about the application of Titanium Cathode in electrolysis and wet metallurgical industry?

Titanium Cathode Plate is mainly used in electrolysis and wet metallurgical industry, new technology of producing starting ti plate, titanium plate of application is of great significance in copper electrolysis production, to improve the quality of electrolytic copper level, production of high purity Yin grade copper, provides a very favorable conditions:

1. Titanium cathode has good chemical stability.In the copper electrolyte, the corrosion rate is 0.011mm/year.

2. The titanium cathode surface forms continuous, dense and uniform oxide film, which is extremely easy to produce copper belt. Therefore, it is not necessary to use soap as the release agent at the beginning of production.

3. Due to the difference in the thermal expansion coefficient of titanium-copper, it is easy to separate the copper plate from the titanium plate and the titanium plate, and can be torn by hand.

4. Titanium cathode has a small proportion of titanium, light weight and only 1/2 of copper, which greatly reduces labor intensity and increases production efficiency.

5. It can be used in high current density to improve the utilization rate of electrolytic cell and expand production capacity.

Our company produces titanium cathode with excellent performance and long service life, which has won unanimous praise from domestic and foreign customers, and has become the world fortune 500 company titanium cathode supplier, maintaining a friendly cooperative relationship.

- Name:

- Ms.Candy Nan

- Tel:

+0086-0917-6758968

+0086-13892437457

- Email:

- btgty@vip.163.com

- WhatsApp:

- 8613892437457

- Address:

- No.21 Road High Technology Zone,Baoji, Shaanxi,China.